Cut Resistance And Its Significance:

To guard against cuts, temperature, and punctures, personal protection equipment (PPE) such as protective gloves is necessary for a variety of industries and professions. Employees are protected by cut-resistant gloves against a variety of hazards, including friction, cutting, electricity, chemicals, and scorching. It's critical to protect your hands. Where there are known hazards, the National Institute for Occupational Safety requires employers to select and use hand protection for their personnel. But If your workplace demand is to be exposed to flames and injuries, cut resistance sleeves should be worn as well.

What these Cut Resistant 5/A3/C PU Coated Gloves can do for you?

These Cut-resistant gloves not only protect the wearer against cuts but also offer some protection from high-temperature changes and severe cut hazards. Because of its outstanding puncture and abrasion resistance, as well as good grip and breathability that comes within them due to the coating material making them a remarkable choice against cut-related hazards and oil interaction.

Who Should Use These Cut Resistant 5/A3/C PU Coated Gloves?

Here are some applications that can use these anti-cut gloves for ultimate safety according to the cut level.

- Warehouse

- Material handling

- Small parts assembly

- Packaging

- Pulp and Paper

Advantages of Cut Resistant 5/A3/C PU Coated Gloves:

Following are some of the benefits of using Cut Resistant gloves.

Convenience and Breathability:

These enable the users to perform the task with ease as they’re made of nylon strands that are of utmost favorable to maintain the airflow. So it will not cause any irritation, allergy, or discomfort. Its lightweight texture doesn’t put any load. You will feel stress-free as hand muscle fatigue risk is no more a concern using them.

Material Handling Ease:

When working with materials like glassware packaging and steel pressing tasks grip is the main thing that you need to avoid breakage and further you need protection against broken glass pieces as their sharp edges can have extremely adverse effects.

Resistance Against Puncture and Cuts:

The basic purpose of these cut-resistant gloves is to provide the ultimate sense of protection regarding abrasions and punctures to its wearer as PU is a slightly tougher material to break this is why you can perform any small material handling tasks with them without much concerns about your hand safety.

Heat Protection:

Cut-resistant gloves are extremely good to provide heat resistance as they are made with certain material that allows the user to deal with hot objects and protect you against burns and hazards that can result from working in severe hot temperature conditions.

Properties Of These Cut Resistant 5/A3/C PU Coated Gloves

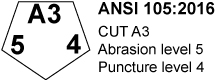

A3 ANSI Cut Level:

A3 - Level 3 safety gloves: can sustain a cutting load of 1000 g to 1499 g. A3 offers light to medium cut resistance.

HPPE Spandex And Nylon Lining:

HPPE creates a lighter, ventilated, and adaptable glove that also helps with cuts and tears prevention. While the nylon and spandex material in the lining composition is unhindered by humidity, which renders Nitrex 244 perfect for food prep, manufacturing, and packaging applications.

13-Gauge Thickness:

Gloves with a gauge of 13 and above are all regarded as highly dexterous, as the greater the gauge thickness, the thinner the glove.

PU Coating:

PU is the ideal material against greasy situations hence we used it to feature an excellent grip on these gloves. The gloves coated with PU are best suited for work that requires accuracy, as well as agility, and sensitivity. Not only that they will protect you against puncture and abrasions good to go with glass handling and assembly products.

Tips To Get The Upgraded Protection You Need At Work:

Check the enlisted specifications and make sure that the gloves you’re choosing are the right material you need at your workplace.

What to Look for in a Cut-Resistant Glove When It Comes to Size:

Your glove should be flexible enough to conform to the shape of your hands rapidly. Large gloves can come off and irritate the wearer, and the extreme foam fitting can be unpleasant.

Look For A Good Grip:

This feature is important especially for simpler material handling, choose gloves with a firm grip.

Coating material:

Select the appropriate coating material to completely shield yourself from the threats you're facing.

Level of Security:

Check the glove's characteristics to be sure they're the correct match for your workplace.

The Gauge's Thickness Is As Follows:

If you prefer thinner gloves, go with a thickness of 10 gauge or higher. Look for breathable liners for a sense of security and comfort.

Conclusion:

We have discussed all the aspects and features of these Cut Resistant 5/A3/C PU Coated Gloves. They do not only cut and abrasion resistance as well as a perfect grip and a sensation of satisfaction, which are all advantages of PU Coated Cut Gloves. They should be used to keep your hand safe while performing any task that involves a risk of injury. Purchase from a reputable retailer, such as NMSafety, that specializes in high-quality items. Their product quality will wow you.